Maximum 3-D printing fans have encountered high quality problems throughout their printing adventure. Midway via a posh venture, issues equivalent to sagging bridges, asymmetric surfaces, or inconsistent filament heating can disrupt growth. Those demanding situations incessantly depart customers pissed off, feeling restricted by means of the era when striving for precision and creativity. On the other hand, what if it’s worthwhile to deal with those hindrances and make your printer smarter, sooner, and extra adaptable to the calls for of your designs? The Ino Trident inductive hotend by means of Plasmics might be offering the answer priced at £339.

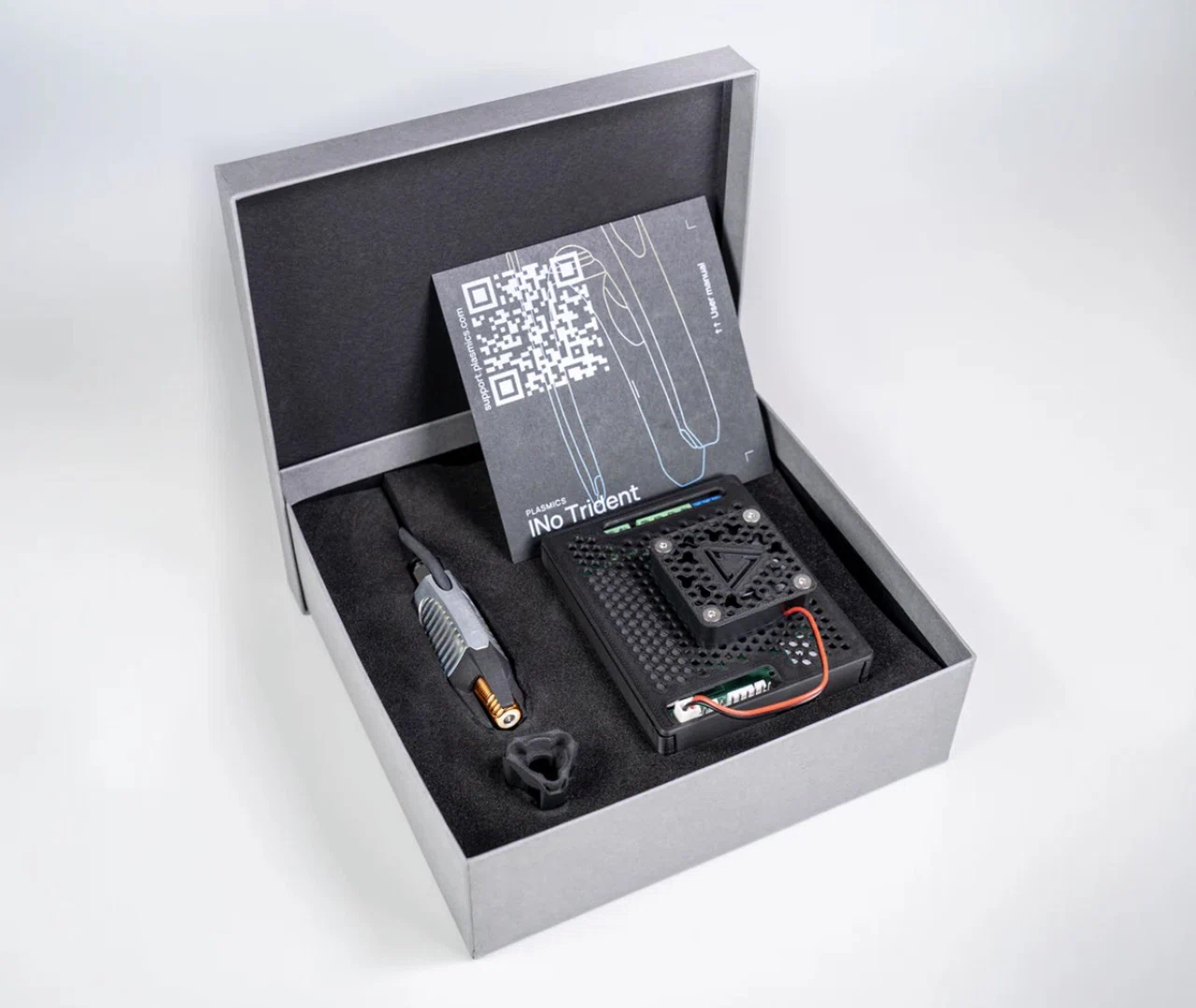

The Ino Trident by means of Plasmics represents a vital development in 3-D printing as the primary commercially to be had inductive hotend. In contrast to conventional hotends that depend on resistive heating parts, this cutting edge design makes use of electromagnetic induction for sooner, extra exact, and energy-efficient temperature keep watch over. By way of incorporating a narrow steel tube as the warmth block, the Ino Trident achieves speedy heating and cooling, enabling intricate, higher-quality prints. This innovation no longer simplest complements efficiency but in addition introduces larger potency and suppleness to the printing procedure.

At its middle, the Ino Trident introduces inductive heating, a departure from conventional resistive strategies. Electromagnetic induction heats the filament with larger velocity and precision, permitting sooner temperature changes, progressed print high quality, and the potential to take care of intricate designs. Whilst nonetheless in its early levels, the hotend has already demonstrated vital possible to handle commonplace 3-D printing demanding situations. Let’s discover how this new era works and what it might imply on your long run tasks.

How Electromagnetic Induction Transforms 3-D Printing

TL;DR Key Takeaways :

- The Ino Trident by means of Plasmics is the sector’s first inductive hotend for 3-D printing, the use of electromagnetic induction for sooner, extra exact, and energy-efficient temperature keep watch over in comparison to conventional resistive heating.

- Electromagnetic induction permits near-instantaneous temperature adjustments, bettering responsiveness for complicated geometries, multi-material prints, and complicated designs.

- Key advantages come with progressed assist constructions, seamless variable temperature printing, and enhanced filament heating potency, leading to higher-quality and extra dependable prints.

- Demanding situations come with slicer device compatibility, inconsistent filament heating at increased glide charges, and the will for workflow simplification to make the era extra obtainable.

- The Ino Trident has the possible to redefine 3-D printing requirements, with long run developments in device and {hardware} anticipated to release its complete features for each hobbyists and execs.

On the core of the Ino Trident lies the main of electromagnetic induction, a technique that essentially adjustments how warmth is generated in 3-D printing. Conventional hotends depend on resistive heating parts to switch warmth to the filament, a procedure that may be gradual and inefficient. Against this, the Ino Trident generates warmth at once inside the steel warmth block via electromagnetic currents, taking into consideration near-instantaneous temperature changes.

This capacity interprets right into a extra responsive machine, in particular advisable for intricate printing eventualities. Whether or not you’re operating with multi-material prints, complicated geometries, or difficult designs, the Ino Trident supplies enhanced keep watch over and precision. Its talent to conform briefly to converting temperature necessities guarantees smoother transitions, decreased defects, and progressed general print high quality.

Key Benefits of Inductive Heating

The Ino Trident’s inductive heating era introduces a number of notable advantages that carry each the potency and high quality of 3-D printing processes:

- Advanced Fortify Buildings: The speedy cooling enabled by means of the inductive machine minimizes sagging in bridges and complements the standard of backside surfaces, even in prints with out assist constructions.

- Seamless Variable Temperature Printing: Fast temperature adjustments throughout a print permit for smoother transitions between fabrics or layers, lowering imperfections and bettering floor finishes.

- Enhanced Filament Heating Potency: Exact and constant heating guarantees dependable extrusion, in particular for filaments that require tight temperature tolerances, equivalent to complicated engineering fabrics.

Those options make the Ino Trident a compelling selection for customers aiming to push the limits of what’s achievable in 3-D printing, providing each sensible advantages and inventive probabilities.

International’s First INDUCTIVE Hotend for 3-D printing

Flick thru extra sources underneath from our in-depth content material masking extra spaces on 3-D printing :

Efficiency Insights and Early Checking out

Early checking out of the Ino Trident published efficiency similar to established hotends just like the E3D V6 in same old printing eventualities. On the other hand, its true strengths turned into obvious in additional tough programs, equivalent to variable temperature keep watch over and complicated geometries. As an example, prints with complicated assist constructions and detailed designs demonstrated noticeable enhancements in floor high quality and dimensional accuracy.

Firmware updates have addressed preliminary demanding situations with speedy temperature adjustments, additional improving the hotend’s reliability. In spite of those developments, some obstacles have been seen throughout checking out. At increased glide charges, asymmetric filament heating every so often disrupted extrusion consistency. Moreover, the loss of slicer device assist for complicated temperature keep watch over required customers to manually alter gcode, complicating workflows for the ones unfamiliar with such processes.

Demanding situations and Spaces for Construction

Whilst the Ino Trident represents a vital bounce ahead in hotend era, a number of demanding situations will have to be addressed to make sure its in style adoption and value:

- Slicer Tool Compatibility: Present slicer device does no longer natively assist the hotend’s variable temperature features, requiring guide changes that can deter much less skilled customers.

- Filament Heating Consistency: At increased glide charges, the warmth block design may just take pleasure in refinements to make sure uniform extrusion and constant efficiency throughout all prerequisites.

- Workflow Simplification: Streamlining the method of enforcing temperature-controlled printing would make the era extra obtainable to a broader vary of customers, from hobbyists to execs.

Addressing those demanding situations will likely be important for unlocking the entire possible of inductive hotends and ensuring their seamless integration into mainstream 3-D printing workflows.

Long term Attainable and Business Have an effect on

The Ino Trident’s cutting edge method to temperature keep watch over holds vital promise for specialised 3-D printing programs. Its talent to supply support-free backside surfaces via exact temperature control may just turn out to be how complicated designs are approached. As slicer device and firmware proceed to adapt, the hotend’s features may just make bigger additional, making it a useful instrument for each hobbyists and execs looking for to reach larger precision and potency.

Having a look forward, the Ino Trident has the possible to set new business requirements for hotend efficiency and effort potency. By way of addressing present obstacles and integrating seamlessly with current workflows, it might pave the best way for extra complicated, flexible, and obtainable 3-D printing answers. This innovation no longer simplest complements the technical features of 3-D printers but in addition permits customers to discover new ingenious and useful probabilities of their tasks. Bounce over to the Plasmics web site for complete specs, data and global pricing.

Media Credit score: PRINTING PERSPECTIVE

Newest latestfreenews Devices Offers

Disclosure: A few of our articles come with associate hyperlinks. If you are going to buy one thing via this sort of hyperlinks, latestfreenews Devices might earn an associate fee. Find out about our Disclosure Coverage.